CMM Measurement

CMM (Coordinate Measuring Machine) measurement is a critical aspect of our quality assurance process. CMM machines are instrumental in precisely measuring the physical geometrical characteristics of objects, ensuring they meet the required specifications and standards in the manufacturing and design industry. CMM Measurement allows us to guarantee the accuracy and quality of our products, contributing to our commitment to excellence and client satisfaction.

The Role of CMM Measurement in Quality Assurance

CMM Measurement serves as a cornerstone in our quality assurance processes at B+E Manufacturing. These machines enable us to conduct comprehensive assessments of the dimensional accuracy, surface finish, and geometrical tolerances of our components. The data obtained from CMM Measurement allows us to validate the conformity of our products to design specifications, ensuring they meet the stringent quality standards expected by our clients and industry regulations.

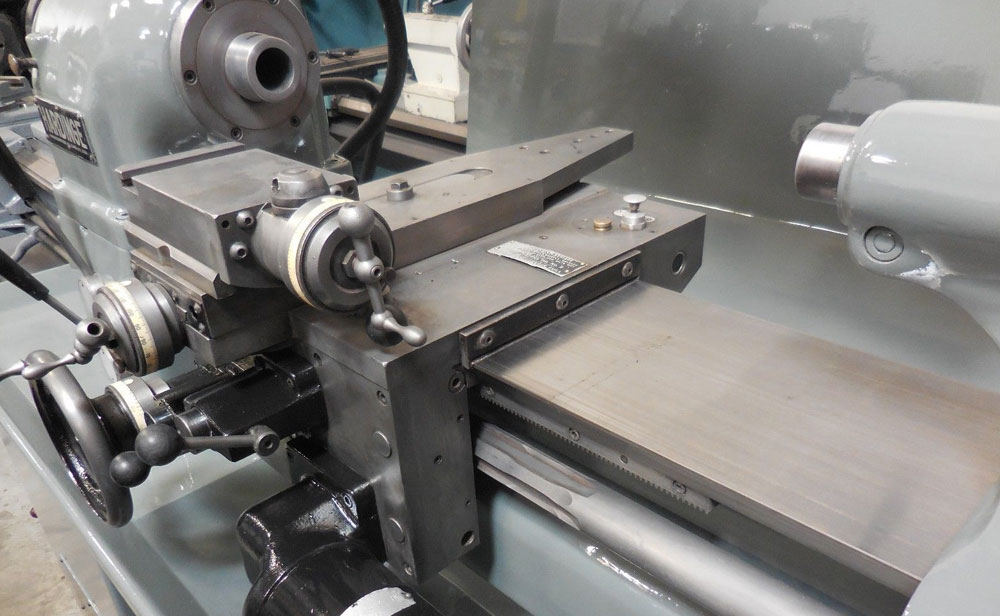

The Assessment Process with CMM Measurement

The assessment process with CMM Measurement involves meticulous planning and execution. We begin by defining the measurement objectives and creating a comprehensive measurement plan. Next, the CMM machine is programmed to capture the required data points, and the measurement process is carried out with precision. The collected data is then analyzed to evaluate the dimensional accuracy and geometric characteristics of the components, providing valuable insights into their quality and conformance to specifications.

Repair Process and CMM Measurement

In instances where components require repair or rework, CMM Measurement plays a crucial role in identifying the areas that need attention. The data obtained from CMM machines aids our engineers in understanding the specific dimensional deviations and imperfections, guiding the repair process with accuracy and efficiency. By leveraging CMM Measurement, we ensure the repaired components meet the original design requirements, maintaining the highest standards of quality in all our products.

Testing Methods and CMM Measurement

CMM measurement is integrated into our rigorous testing methods at B+E Manufacturing. We utilize CMM machines to conduct dimensional inspections, form and position evaluations, and surface profile assessments. These testing methods, supported by CMM Measurement, enable us to validate the integrity and precision of our components, ensuring they meet the stringent quality benchmarks set by our company and the industry.

Materials Used in CMM Measurement

The materials used in CMM measurement and B+E Manufacturing encompass high-precision probes, styli, and fixtures, ensuring the accurate and reliable measurement of intricate components. Our commitment to utilizing top-grade materials in CMM Measurement underscores our dedication to precision and quality in every aspect of our manufacturing process.