Welcome to B+E Manufacturing, where precision, innovation, and excellence converge to shape the future of engineering solutions. With a legacy spanning several decades, we have meticulously honed our expertise in delivering unparalleled manufacturing and design services to a diverse array of industries.

Our unwavering commitment to quality and precision forms the cornerstone of every project we undertake. From the inception of a concept to the final product, we stand ready to exceed your expectations and deliver results that meet the most stringent standards of quality and precision in the industry.

Quality Assurance Equipment

- Coordinate Measurement Machine Numerex/Zeiss 40” x 40”, DC controls

- Profile Projector Mitutoyo 14”

- Master Gage Block Set, Gage Pin, Gage Ball Sets, Height Stands, Micrometers (I.d. and o.d.)

- Digital Veneers, Digital Depth Micrometers, Digital Thread Micrometers, etc.

- Height Stands, ID Micrometers, OD Micrometers

- Hardness Tester

Precision Redefined: Where Quality Meets Expertise

At the heart of our operations lies our unwavering dedication to precision, underpinned by cutting-edge technologies and a team of seasoned professionals. Our state-of-the-art facilities are equipped with advanced machinery and tools, enabling us to bring even the most intricate designs to life with unparalleled accuracy.

Every project we undertake undergoes rigorous testing and inspection, ensuring each component meets the most exacting standards. With our meticulous approach and steadfast commitment to excellence, we stand as a beacon of quality in the realm of manufacturing and design. Our team of skilled engineers and designers works seamlessly to transform your vision into reality, and our commitment to precision and innovation ensures every project is met with the highest levels of craftsmanship and attention to detail.

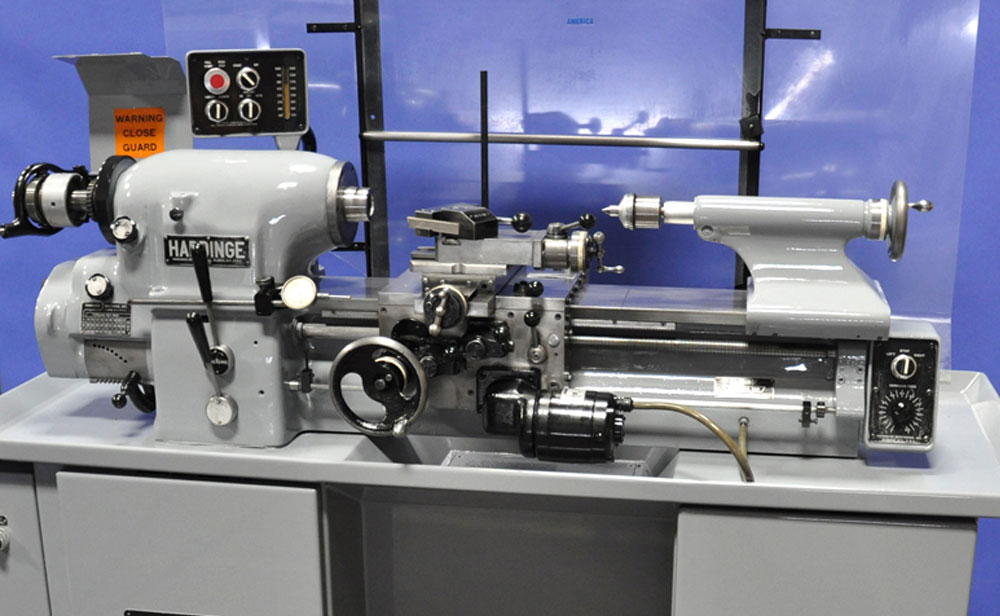

CMM Measurement

Our commitment to precision is ingrained in every aspect of our operations, and this dedication is exemplified through our advanced Coordinate Measuring Machine (CMM) capabilities. The CMM serves as the bedrock of our measurement proficiency, empowering us to conduct meticulous inspections and verifications with unparalleled accuracy. Through the utilization of this cutting-edge technology, we can perform comprehensive dimensional analysis, geometric dimensioning and tolerancing (GD&T) inspections, and intricate surface measurements. This meticulous approach ensures that every component meets the highest quality requirements, guaranteeing the delivery of top-quality products.

Our CMM capabilities are seamlessly integrated into our quality assurance processes, allowing us to uphold the highest standards of precision and accuracy throughout every stage of production. The utilization of advanced CMM technology enables us to carefully verify the dimensional accuracy and geometric integrity of each component, ensuring they meet the most stringent specifications. By leveraging this state-of-the-art technology, we ensure the delivery of quality products and surpass industry standards while instilling confidence in our clients regarding the quality and precision of our manufacturing process.

Our CMM technology empowers us to conduct intricate surface measurements, enabling us to assess the form, profile, and finish of components with great precision. This comprehensive approach to measurement and verification is integral to our commitment to consistently delivering high-end products that exceed our clients’ expectations. Contact us today to learn more about our qualifications in CMM machining and our dedication to quality assurance.