Building Inspiring Spaces

Welcome to B+E Manufacturing, a trusted provider of optimal machining solutions in manufacturing and design. With our extensive experience and expertise, we offer a comprehensive range of services to meet your specific needs. Our team of professionals utilizes advanced techniques and state-of-the-art equipment to ensure precision, efficiency, and superior craftsmanship.

We have established robust partnerships to offer comprehensive solutions to our valued clients. We collaborate with companies that specialize in services or provide parts using equipment not available in-house, such as stamping, heat-treating, painting, plating, and more. This strategic collaboration enables us to go above and beyond the initial scope of work outlined in our equipment list, providing a service that exceeds expectations.

Quality Assurance

Quality assurance is a top priority at B+E. We take pride in our excellent track record of delivering correct parts to the satisfaction of our customers. Our production processes are ISO 9001-2000 registered, demonstrating our commitment to continuous improvement and ensuring customer satisfaction.

We are honored to have earned the trust of our customers through our dedication to quality and customer service.

Design and Engineering

Our team of skilled engineers and designers is dedicated to delivering innovative and efficient solutions for your manufacturing needs. From conceptualization to detailed design, we utilize the latest software and tools to create precise and functional designs that meet your specifications.

CNC Machining

With our state-of-the-art CNC machines, we provide high-precision machining services that ensure accuracy and consistency in every component. Our experienced machinists are adept at programming and operating these advanced machines, allowing us to produce complex parts with tight tolerances, intricate geometries, and superior surface finishes.

Manual Machining

We offer manual machining services for projects that require a more hands-on approach. Our talented machinists utilize traditional machining techniques and equipment to craft custom parts and prototypes with meticulous attention to detail and craftsmanship.

Fabrication

Our fabrication services encompass various processes, including cutting, bending, welding, and assembly. Whether you need sheet metal fabrication or structural fabrication, our team has the expertise and resources to deliver high-quality components or complete assemblies that meet your requirements. Reach out to us today to learn more about the services we provide and see how we can help you and your business.

Designing and Engineering

With more than 50 years of experience in manufacturing, we have established ourselves as a reputable provider of design and engineering services. This extensive experience has allowed us to develop a deep understanding of the intricacies of numerous industries, enabling us to deliver reliable and high-quality solutions. We’ve honed our design and engineering capabilities to meet each project’s unique requirements and challenges, ensuring client satisfaction and successful outcomes.

Contract Manufacturing Services in Design and Engineering

Contract manufacturing services play a crucial role in today’s global market, enabling companies to outsource the production of their goods to specialized manufacturers. These manufacturers, known as contract manufacturers, provide various services, including design, production, assembly, and packaging. By leveraging their expertise and resources, contract manufacturers can help companies bring their products to market efficiently and cost-effectively.

Benefits of Contract Manufacturing Services

Engaging contract manufacturing services offers several advantages for companies. Firstly, it allows them to focus on their core capabilities, such as product development, marketing, and sales, while leaving the manufacturing process to experts. This labor allocation enables companies to streamline their operations and divide resources more effectively. Additionally, contract manufacturers often have specialized knowledge and experience in specific industries or technologies, ensuring the production process is carried out with precision and efficiency.

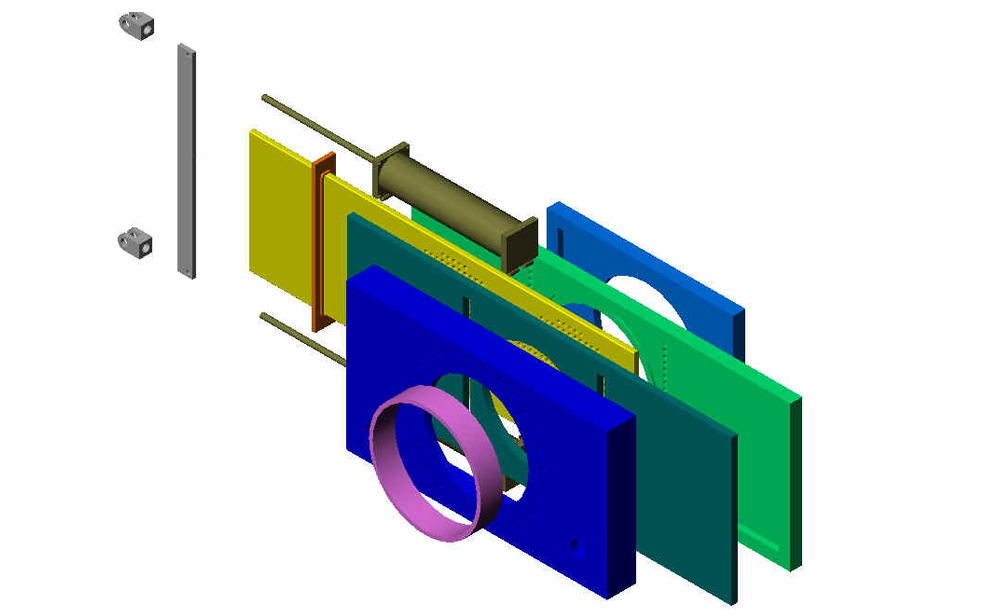

Enhancing Contract Manufacturing Services with SolidWorks

Our expertise in contract manufacturing services extends beyond design creation and simulations. By leveraging the capabilities of the 3D computer-aided engineering program SolidWorks, we can offer comprehensive solutions to our clients. The program allows us to perform advanced analyses, such as finite element analysis (FEA), enabling us to evaluate factors such as stress distribution and thermal performance. This thorough approach ensures that the final product meets design specifications and performs optimally under real-world conditions.

The efficient utilization of SolidWorks empowers our engineers to streamline their workflows, reducing design time and increasing productivity. The program’s intuitive interface and extensive toolset enable us to collaborate effectively on projects, facilitating concurrent work on different aspects of a design. This collaborative approach accelerates the design process, promotes cross-functional communication, and enhances the overall quality of the design and engineering work.

Optimizing Workflows and Collaboration in Contract Manufacturing Services

Our contract manufacturing services are strengthened by our extensive experience in manufacturing, our utilization of SolidWorks, and our commitment to delivering efficient, comprehensive, and high-quality work. With our expertise and the integration of 3D computer-aided software, we can meet the unique requirements of various industries, ensuring client satisfaction and successful project outcomes.

CNC Machining

CNC machining, also known as Computer Numerical Control machining, is a sophisticated manufacturing process that utilizes computer-controlled machines to shape and create precise components. This transformative technology has revolutionized the aerospace, automotive, and medical industries, offering unparalleled precision, efficiency, and versatility. By harnessing the power of advanced software and automation, CNC machining has become an indispensable tool for manufacturers seeking to achieve high-quality, customized, and efficient production.

From manual lathes, mills, and grinders to large-capacity CNC mills and lathes, B+E has the machine tools to handle any size of production. Our staff is trained and capable of using our machines to the level of precision needed.

Precision & Engineering for CNC Machining Capabilities

CNC machining is renowned for its ability to achieve exceptional precision and accuracy in manufacturing processes. By utilizing computer-controlled machines, companies can ensure consistent and repeatable results, allowing for the production of intricate designs with tight tolerances. This level of precision is crucial in industries where the smallest deviation can have significant consequences. Our CNC equipment list includes the following:

- Ooya VMC RE 6M, 98” x 72”

- Ooya VMC RE 5M, 56” x 68”

- Toshiba HMC 100” x 80” x 60” 3 Axis; 0.0010 index rotary table; angled head

- SNK 4M VMC, 158” x 98” x 60”, 3 Axis machine with 900 angled head (4-axis)

- HAAS VF 2 VMC

- Haas VF 5 VMC, 50 x 26 x 25”, 26 position tool changer

- Haas VF 9 VMC, 84 x 40 x 30”, 32 position tool changer

- HAAS ST-20Y Lathe, 8” Swing x 13”

- HAAS SL-40 Lathe, 40” Swing x 80”

- Toyoda VMC, 118” x 59” x 48”, 60 position tool changer, 3-axis machine w/ 900 angled head (4-axis)

Versatility

The versatility of CNC machining is one of its key advantages. These machines offer a wide range of capabilities that can be tailored to meet the needs of various industries and applications. Whether it’s creating complex 3D shapes, drilling precise holes, or producing intricate patterns, we can adapt to different requirements and deliver high-quality components that meet the most demanding specifications.

Material Compatibility

CNC machines are compatible with a diverse range of materials, making them suitable for a wide array of projects. From metals such as aluminum, steel, stainless steel, and titanium to plastics and composites, we can work with different materials based on customer requirements. This flexibility allows for the production of components suitable for specific applications, guaranteeing the final product meets the desired performance and durability standards.

Efficiency and Speed

CNC machining is known for its efficiency and speed in production processes. The automated nature of these machines reduces the need for extensive manual labor, minimizing the risk of human error and increasing productivity. This translates into faster turnaround times, enabling us to meet tight deadlines and deliver orders in a fashionable manner, which is vital for industries where time-to-market is of the utmost importance.

Customization

One of the significant advantages of CNC machining is its ability to provide easy customization and design flexibility. With computer-controlled machines, we can quickly adapt to design changes or create unique parts based on specific customer requirements. This level of customization ensures that clients receive parts that perfectly align with their project needs, resulting in enhanced customer satisfaction and the ability to tackle diverse manufacturing challenges.

Quality Assurance

CNC machining ensures consistent and high-quality production throughout the manufacturing process. The precise instructions programmed into the CNC machines minimize the risk of errors and defects, resulting in superior component quality. Additionally, we implement rigorous quality control measures, including inspections and testing on each manufactured part, to ensure every part meets the highest industry standards.

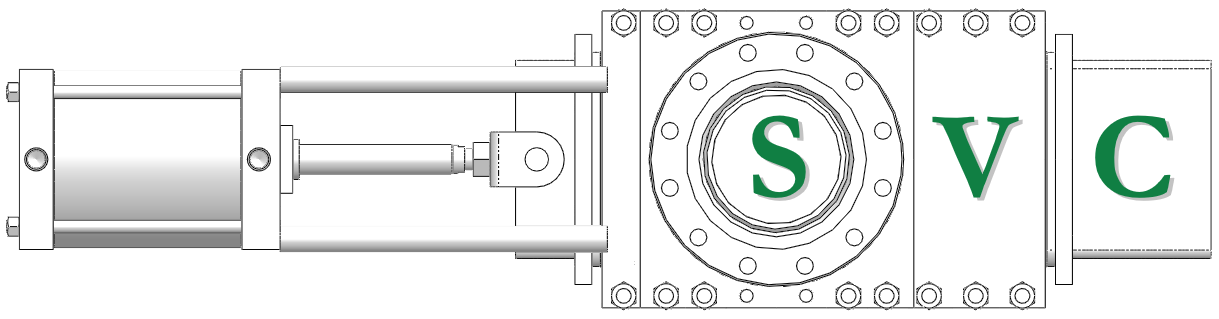

Our commitment to quality assurance ensures customers receive products of superb quality and reliability. Take a look at our CNC Equipment and Contact us today to let us start machining of your required components and finding solutions for valve problems.

Manual Machining

With a steadfast dedication to precision and a resolute commitment to meeting our client’s unique requirements, we consistently strive to deliver high-quality results for every project, no matter the complexity or scale.

Tailored Precision: Collaborative Approach to Custom Machining

At B+E Manufacturing, we firmly believe in fostering a collaborative approach regarding custom machining. We begin by engaging in detailed consultations with our clients, meticulously gathering their specific requirements and expectations. By actively listening to their needs, we ensure we have a broad understanding of the project’s scope, allowing us to tailor our services accordingly. Throughout the entire process, we maintain open lines of communication, encouraging feedback and input from our clients to ensure their complete satisfaction.

Mastering the Art of Manual Machining

With our state-of-the-art facility, we harness the power of advanced manual machining techniques to deliver exceptional results. Our highly skilled machinists possess a wealth of experience in turning, milling, and grinding, allowing us to tackle the most intricate and demanding projects. From intricate components to complex geometries, our team is adept at executing precision work with unwavering accuracy, assuring each piece meets the exact specifications outlined by our clients.

Quality Control: Ensuring Precision and Accuracy

We understand the critical importance of quality control in the realm of custom machining. To ensure precision and accuracy, we have implemented rigorous inspection processes throughout every stage of production. Equipped with advanced measuring instruments and testing equipment, our skilled quality control team carefully verifies each component, leaving no room for error. By adhering to strict quality standards, we guarantee our clients will receive products that meet and exceed their expectations.

Delivering Excellence: On-Time Delivery and Customer Satisfaction

We recognize timely delivery is paramount in the world of custom machining. With our efficient production planning and streamlined processes, we prioritize meeting deadlines without compromising quality. Our dedicated team works diligently to ensure projects are completed within the agreed-upon timeframe, allowing our clients to proceed with their operations seamlessly.

Customer Satisfaction

Above all, our ultimate goal is to achieve customer satisfaction. By combining our technical expertise, collaborative approach, and unwavering commitment to quality, we aim to build long-lasting partnerships with our clients, earning their trust and becoming their go-to provider for all their custom machining needs.

Fabrication

Advanced Fabricating Services for Complex Components

At B+E, our fabricating services are designed to handle even the most complex components with precision and expertise. Our skilled technicians are well-versed in the intricacies of fabricating sophisticated parts, ensuring exceptional accuracy and quality. With cutting-edge equipment and a commitment to continuous improvement, we have the capabilities to tackle challenging fabricating projects and deliver superior results.

Specialized Welding Techniques for Enhanced Strength and Durability

Concerning welding, we employ specialized techniques that enhance the strength and durability of welded components. Our certified welders are highly skilled in various welding processes, including TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and arc welding. By carefully selecting the appropriate welding method and controlling welding parameters, we achieve welds of exceptional quality, ensuring the longevity and performance of fabricated components.

Efficient Assembly Solutions for Large-Scale Components

B+E Manufacturing excels in providing efficient assembly solutions, particularly for larger components. Our streamlined assembly processes and meticulous attention to detail enable us to efficiently assemble complex structures, ensuring proper alignment and functionality. Through the utilization of advanced equipment and tools, we optimize assembly operations, minimizing downtime and maximizing productivity.

Stringent Quality Control Measures for Fabricated Components

To guarantee the highest quality of fabricated components, B+E Solutions implements stringent quality control procedures throughout the fabricating process. Our dedicated quality assurance team conducts comprehensive inspections and tests at each stage, from material verification to final assembly. By utilizing advanced inspection equipment, such as coordinate measuring machines (CMMs), we ensure fabricated components meet strict dimensional accuracy, structural integrity, and specification requirements.

Material Selection Expertise for Optimal Performance

We understand the critical role material selection plays in achieving optimal performance for fabricated components. Our experienced engineers and material specialists work closely with clients to identify the most suitable materials for their specific applications. By considering factors such as mechanical properties, corrosion resistance, and thermal stability, we ensure the chosen materials deliver exceptional performance and longevity.

Commitment to Customer Satisfaction and Timely Delivery

At B+E, we are dedicated to providing top-notch fabricating services to ensure customer satisfaction and timely delivery. We understand the importance of meeting project deadlines and strive to exceed expectations in every aspect of our work. Our team works closely with clients, maintaining open lines of communication throughout the fabrication process. We are committed to delivering high-quality fabricated components on schedule, allowing our clients to stay on track with their projects and achieve their goals.